Contract Manufacturing Machine Building

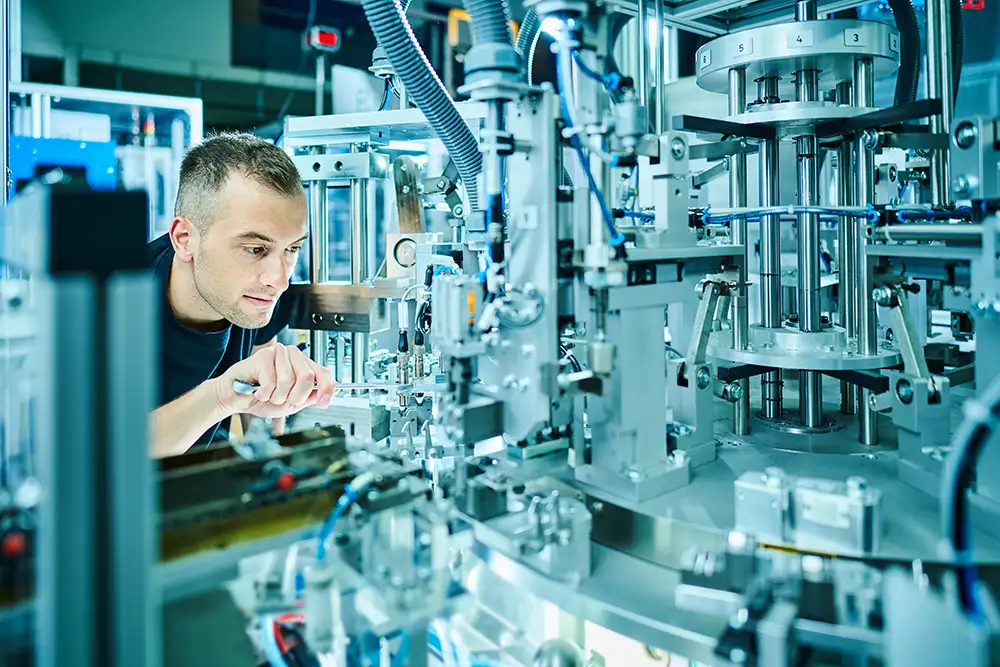

Contract manufacturing and machine building – Benefit from outsourcing production tasks to us as an external company. By entrusting a specialized manufacturing company with the task of building machines for your own contract manufacturing according to individual requirements, significant resources can be saved. This external manufacturing partnership allows the company to focus on core competencies while outsourcing the production of certain components to experts.

This is where we, Probotec, come into play as your contract manufacturer for machines. The special thing is that as a contract manufacturing company, we can build various types of machines for you.

At a glance – These advantages await you:

- Cost and time savings

- Flexibly adjustable production capacities

- Access to specialized expertise

- Individually suitable machine types

- Focus on core competencies

Contract Manufacturing and Machine Building - Efficient Techniques

Large-scale machine components – they form the basis for various industries in machine building. Reliable and high-quality building of components is therefore essential. There are different processes for suitable solutions and end products:

Assembly manufacturing refers to the building of complex assemblies by combining multiple individual parts. The individual parts are either built by the company itself or by external partners and then assembled into a complete assembly. This process allows companies to build complex products without having to perform all the necessary building steps themselves.

An all-round service for your contract manufacturing

Contract Manufacturing and Machine Building - Our production capabilities for your products

- Cam-controlled assembly systems for production volumes of up to 250 million units per year

- Complete project management during machine building

- Variety of variants on a single machine with efficient setup processes

- Production-related documentation and ensuring all relevant features and information

- Procurement of all necessary materials, including storage

Important components of contract manufacturing

-

Analysis of production requirements:

Before contract manufacturing for machine building begins, it is important to analyze the exact requirements of the clients. This includes determining the required parts or assemblies, their specifications, quantities, and quality standards. This allows for a clear definition of the machine to be built and forms the basis for the subsequent steps -

Selection of manufacturing partners:

Criteria such as expertise, experience, capacities, quality assurance systems, and pricing are taken into account when selecting manufacturing partners. This is crucial for the success of contract manufacturing. -

Contractual agreements:

These contracts define the exact services, delivery times, quality standards, prices, and other relevant conditions. The contractual agreement creates transparency and binding commitments for both parties. -

Communication:

Continuous communication between both parties is important throughout the entire process of contract manufacturing in machine building. Open information exchange allows for the fulfillment of requirements and schedules. This allows for timely clarification of any questions or issues and ensures the quality of the built parts or assemblies.. -

Quality control and monitoring:

This includes checking the built components or assemblies for their quality, dimensional accuracy, and functionality. Regular inspections and random sampling ensure that the built products meet the requirements. Continuous inspections contribute to ensuring the required standards. -

Delivery and logistics:

After completion of building, the finished parts or assemblies are delivered back to the company. Logistics and transportation need to be carefully planned to ensure timely delivery. Various logistics options can be used.

As we provide full-service solutions, we also offer suitable storage for your needs. You can rely on sufficient storage space for semi-finished products and finished parts.