Assembly

Assembly plays an important role in various industries. It is the process of combining products or

components to create a finished end product – a unit.

Through careful planning, preparation, assembly, and quality control, we at Probotec develop

efficient assembly processes to deliver high-quality end products that inspire.

The individual steps of assembly

The process of assembly includes several steps that ensure that the final product meets all requirements and specifications.

Before the actual assembly process begins, it is important to understand the exact requirements and specifications of the end product. This includes considering the materials and tools needed and determining the most efficient process.

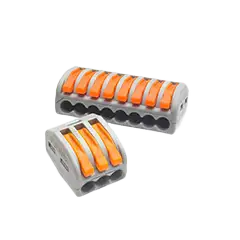

In this phase of assembly, the individual parts are assembled according to specific instructions and plans using assembly equipment. It may be necessary to use special tools or fixtures to securely and precisely connect the components.

Benefits of assembly for your company

Assembly allows companies to optimize their processes and achieve valuable efficiency gains. By combining various items or components into a new unit, products can be produced faster and more effectively. This leads to improved productivity, shorter delivery times, and faster fulfillment of customer wishes.

Assembly at Probotec offers your company the opportunity to respond faster and more efficiently to the individual needs and requirements of customers. By assembling different items or components, customized solutions can be offered. You benefit from customization and also have the opportunity to adapt products according to your own preferences. By offering customers tailored solutions and being flexible in meeting their needs, customer loyalty is strengthened, which can lead to positive recommendations.

Another advantage of our assembly service is cost optimization. By using efficient processes and pooling resources, you can reduce production costs. In addition, we ensure optimized inventory management by keeping only the necessary components or items in stock.

Furthermore, you will receive comprehensive quality control from us. Before assembling the items or components, each of them is individually inspected and any defective items are sorted out. In short, we ensure that only products of the highest quality are delivered to you.