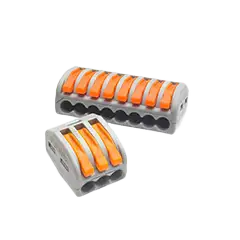

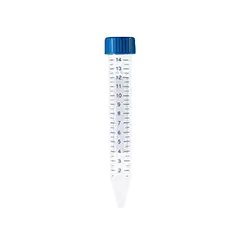

ASSEMBLY & PACKAGING

OF PLASTIC PRODUCTS.

MANUFACTURING IN COMBINATION WITH MECHANICAL ENGINEERING

- In-house Assembly Plant allows for flexible adjustments

- Over 20 years of experience in building assembly systems

- Manufacturing on a custom-made assembly system

EVERYTHING FROM A SINGLE SOURCE

We assemble 1-8 components on a single system. The annual output per system ranges from 1 to 250 million units per year.

- Plant construction

- Quality assurance

- Procurement of semi-finished products & packaging materials

- Ensuring availability

Start highly automated in your next project

We can undertake projects for industries such as Food & Beverages, Healthcare, Beauty & Home, Construction, or the Automotive industry. Your production facility, environment, and processes will be customized specifically for you and your project.

- 10 years of experience as an automotive supplier

- 20 years of experience in mechanical engineering

- Delivered 10 billion parts

You supply the components - we take care of the rest

If you require the components for a project to be fully assembled but lack expertise in assembly, many questions may arise. Where can I obtain the appropriate production facility? Where do I operate the facility? Who can operate and repair the facility? These are just a few examples.

By outsourcing your project to Probotec, we handle all these questions for you. You can focus on your core business while we take care of the rest.

We manage all the necessary steps on your behalf. All we need are your components or drawings.

With us, you can access 20 years of experience in mechanical engineering. Our sister company, Contexo GmbH, has successfully realized over 500 custom-built machines according to customer requirements.

Ensuring the assembly of your products is not the only aspect to consider. The handling of parts, conditioning, and packaging are also developed specifically according to the requirements of your products.

We perform 100% inline testing of your parts on our systems. Whether it's leak testing, correct assembly, deformations, or encapsulations, we incorporate the appropriate testing equipment to meet the requirements. Additionally, we can introduce quality assurance measures outside of the machine process.

An assembly system is a significant capital investment. Therefore, we offer various concepts, ranging from leasing options to assuming the costs based on contractually guaranteed quantities. We would be happy to provide you with a suitable offer in this regard.